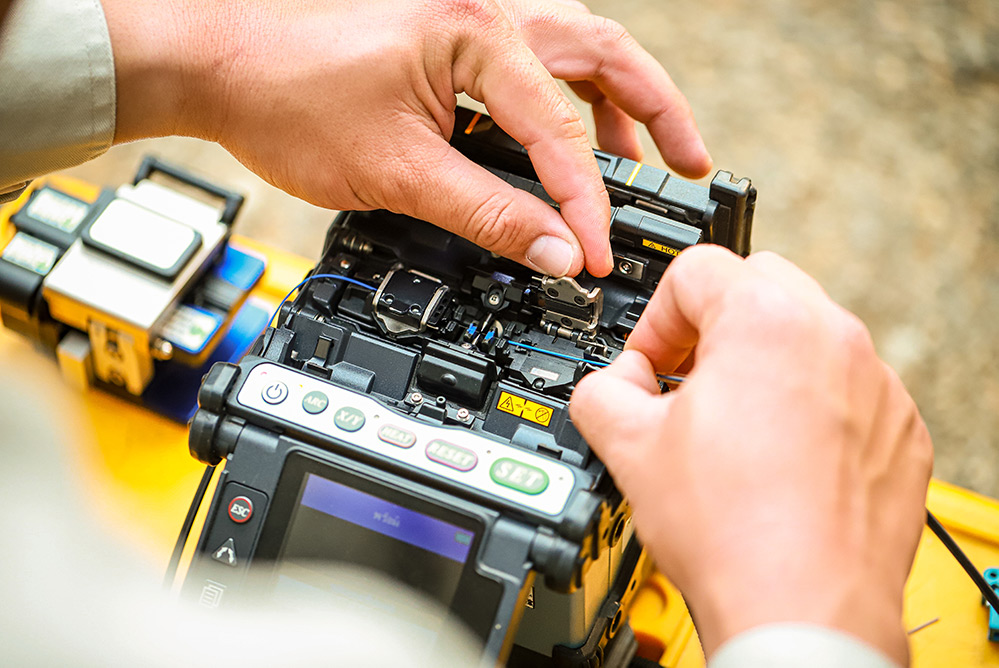

Fibre Optic Splicing

A robust and reliable fibre optic network is the backbone of any telecommunications company.

Full Fibre Solutions offer precise fibre splicing services to lay the foundation for further growth. Whether you are looking to repair damaged cables to maintain uptime, expand a network into a new location or are planning a complex expansion, we have the proven experience and cutting-edge technology to futureproof your network.

A critical process in establishing reliable and high-performance fibre optic networks, splicing involves the precise joining of fibre optic cables to ensure continuous and efficient signal transmission.

From single-mode cabling for higher bandwidth applications or multi-mode cabling for short-distance data transmission, Full Fibre Solutions are here to assist.

Ribbon splicing addresses the challenge of managing individual fibres, providing a high-density and overall more efficient solution for networks.

Full Fibre Solutions' ribbon splicing help you maximise network efficiency and handle the ever-growing demands of data transmission, laying the groundwork for future growth.

The two primary techniques are fusion splicing and mechanical splicing.

Fusion splicing results in a low-loss and high-strength joint while mechanical splicing results in a higher loss. However, mechanical splicing is the more cost-effective option and is often sufficient for lower-bandwidth applications where signal loss is less critical.

Fusion splicing typically results in an insertion loss of 0.02 to 0.05 dB per splice. Mechanical splicing usually has higher insertion loss, around 0.1 to 0.2 dB per splice.

Yes – This will help you to establish a clear history of the network's physical layer, aiding in efficient management and future planning.

Yes – Maintaining a controlled environment during splicing is essential. Our experienced technicians account for:

Extreme temperatures can impact the splicing process and the adhesive used, requiring a moderate temperature range to ensure proper curing and splice integrity.

High humidity levels can introduce moisture into the splice area, potentially leading to signal loss and performance degradation.

Cleanliness – Dust and other contaminants can settle on the fibre ends during splicing, creating imperfections that affect light transmission. Our team takes steps to create a clean and dust-free environment, allowing for precise and reliable connections.

The Full Fibre Solutions team uses high-precision and regularly-calibrated equipment, in addition to taking the aforementioned precautions to control the splicing environment. They also make use of high-quality splice protection sleeves to help maintain the integrity of the splice.

Splice protection involves the use of heat-shrink sleeves or other protective enclosures to safeguard the splice joint from environmental and mechanical damage, including standard heat-shrink sleeves, ribbon splice protectors for ribbon fibres and mechanical enclosures for added durability.

If you have any questions or wish to enquire into our services, please get in touch at:

Unit 58

Flexspace

Bolton

BL3 2NZ