The ever-growing demand for data has propelled fibre optic networks to the forefront of communication. But building and maintaining these networks relies on a crucial process – fibre optic splicing.

While each method offers distinct advantages and disadvantages, the question of which one is best for your situation depends on the nuances of your project, budget and needs. This blog post will compare the finer points of these primary methods of splicing.

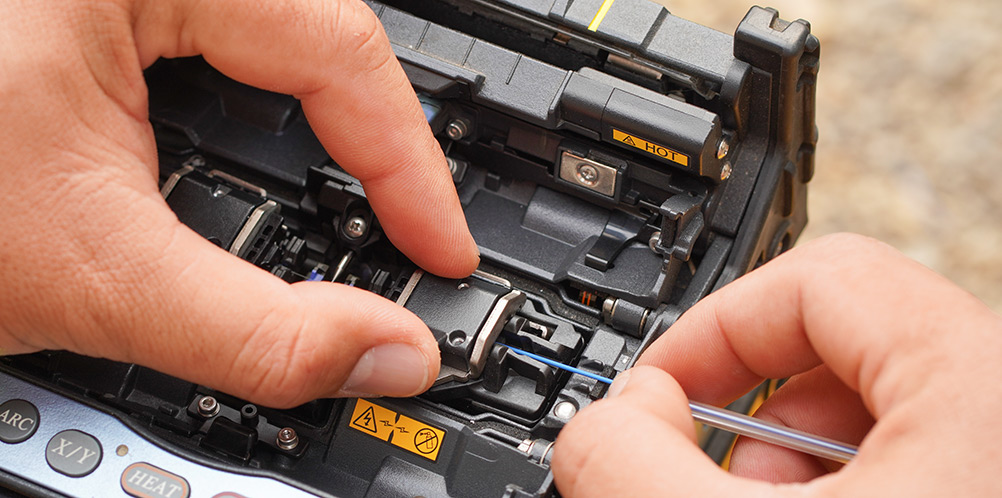

Fusion Splicing for Permanent Light Highways

Just as an arc welder connects sheets of metal together, fusion splicing connects the hair-thing fibres that make up fibre optic for a near-lossless connection.

While the technology used stretches back to the first Fujikura machines back in the 1970s, fusion splicing is still going strong 50 years later and boasts several advantages when compared to mechanical splicing.

Superior performance

Fusion splicing delivers the gold standard in signal transmission. With minimal signal lost in the splicing process, light signals can travel seamlessly from point A to point B, making it the perfect choice for long-distance networks where maintaining signal strength is paramount. For this reason, fusion splicing is also relied upon by data centres to manage the massive flow of information with minimal disruption.

Long-Lasting Connections

The fusion process creates a permanent weld to fuse the two fibres into a single unified strand. This translates to exceptional durability, creating a reliable connection that can withstand the test of time with minimal degradation and no risk of a connection coming loose, providing peace of mind for mission-critical applications.

However, this doesn't mean that fusion splicing is singularly ‘better than mechanical splicing – This performance comes with a few asterisks.

Higher Investment

The delicate nature of fusion splicing requires specialist equipment and training in order for it to be carried out to its fullest potential. While this expertise ensures a long-lasting and high-performing connection, this also leads to a higher upfront cost.

A Longer Splicing Process

Similarly, while the end result may be worth the wait, the meticulous nature of fusion splicing translates to a slower process when compared to some alternatives. This may not be a dealbreaker for most permanent installations, but it's a factor to be considered in situations where timescales are a concern.

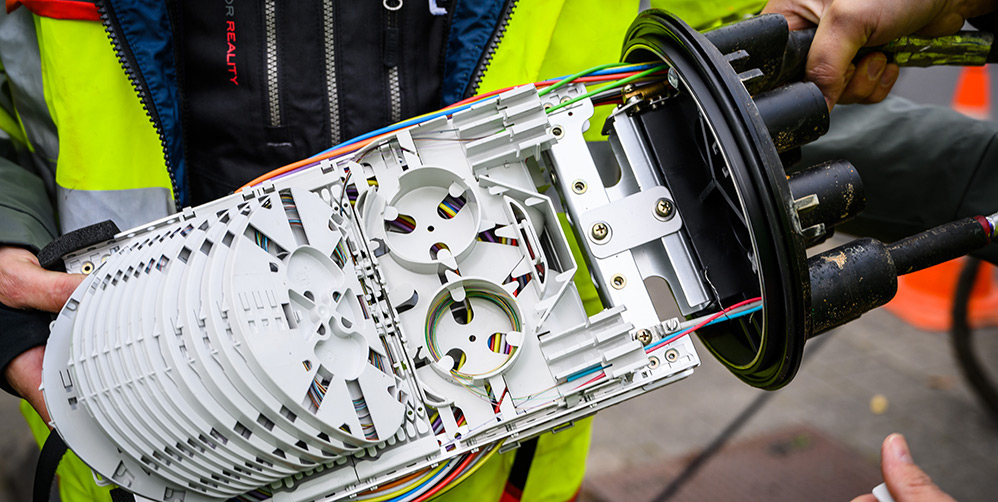

Mechanical Splicing for Flexibility

While fusion splicing ensures a strong permanent connection, there are situations in the fibre optic world where adaptability is paramount.

This is where mechanical splicing comes into play, offering a unique combination of speed and flexibility for quick yet efficient connections.

Speedier Connections

As it relies on mechanical connections rather than permanent welding, the process of mechanical splicing is significantly faster than fusion splicing. This makes it the ideal option for temporary deployments, like setting up fibre at an event venue or for rapid restoration efforts.

Lower Cost

As it does not rely on specialist, high-tech equipment, mechanical splicing stands as a more budget-friendly option in situations where a permanent connection isn't crucial or even necessary.

Adaptability

Indeed, this lack of a permanent connection is a benefit in and of itself. Should a mistake be made during splicing, dissembling and re-connecting the mechanical splice is far simpler and cheaper than compared to amending a fusions splice. This degree of flexibility can be an asset where troubleshooting or adjustments might be needed.

Yet despite these undeniable advantages, it's important to acknowledge the limitations of mechanical splicing.

Performance Compromise

The physical connection point inherent in mechanical splicing can introduce signal loss. This makes it unsuitable for high-performance applications like building long-distance networks or data centres where signal integrity is critical.

Limited Durability

Simply put, mechanical splices are not meant as a long-term solution. They are less durable than fusion splices and may degrade over time, potentially impacting connection quality.

Choosing the best way forwards for your project

As you've just seen, despite the touted benefits of fusion splicing there is no clear winner when it comes to fibre splicing.

For example, even during more permanent projects or expansions, there may be an element of future intended troubleshooting and/or budgetary constraints that mean you'll have to immediately rely upon mechanical splicing.

Just as there are no one-size-fits-all answers, so too do Full Fibre Solutions provide customised plans for all your fibre optic and cabling needs. We consider every possible factor and facet of your project when designing splicing solutions and choosing which technique would be best, identifying your priorities and choosing the method that aligns best with them.